We offer a range of innovative additional services that go beyond traditional product development.

Prototyping

Prototyping

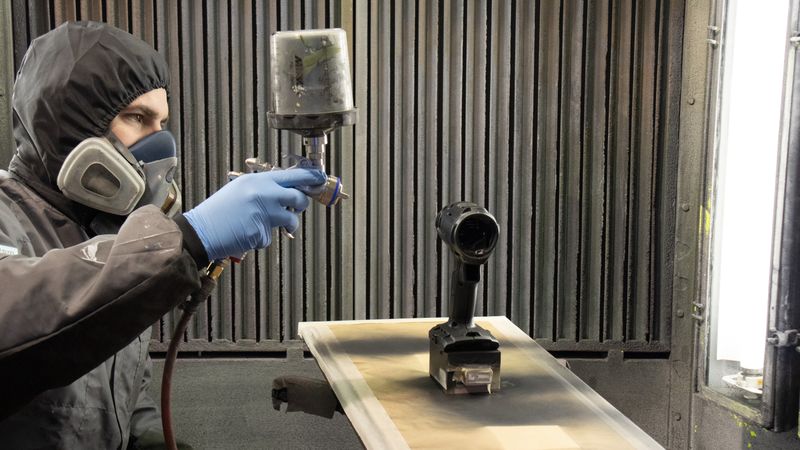

A high-quality prototype is the decisive step in turning a vision into a tangible product. As your expert partner for prototyping, model making, and small-batch production, we accompany you every step of the way.

Covering more than 1,500 m², BUSSE Production combines state-of-the-art machinery, technical expertise, and the manpower required to manufacture near-series prototypes, complex functional models, and sophisticated small series.

Get in touch with us

Find out more at BUSSE Production – our specialists for near-series models and manufacturing on 1,500 m²

Our expertise & capacities

We combine all necessary machining processes and process steps under one roof – from the initial idea to final acceptance. This enables us to guarantee maximum efficiency and quality for your project.

Machining, conventional and CNC

Milling of free-form surfaces with multi-sided machining

Sheet metal processing*, flowdrill, welding

Painting (including special paints such as EMV, Soft-Touch, Nextel etc.)

Grinding, polishing, surface finishing

Cross-material assembly of components

Rapid prototyping: SLS, STL, DLP, CUSING etc.*

Injection molding up to 180 g in small series, vacuum casting technology*

Investment casting in aluminum and magnesium

Components made from fiber-plastic composites (GFK, CFK)*

(* We carry out some processes directly in-house, while others are implemented with our long-standing partners.)

Contact us nowReferences

Our premises

3 flexibly divisible assembly areas

Plenty of space on 1,000 m²

Lightweight construction hall with an additional 450 m² of material storage and further customer-specific testing and assembly areas

Extensive material / standard parts warehouse

Project-related material flow and storage resources

Diverse machinery

Your consent is required. This content is hosted by a third party (www.youtube.com). By showing the external content you accept the the terms and conditions of www.youtube.com.

Together towards success – with our experience, we will take your industrial design project to the next level! Have we piqued your interest?

Latest Publications