Sustainable Development

Sustainability - from buzzword to concrete implementation in product development

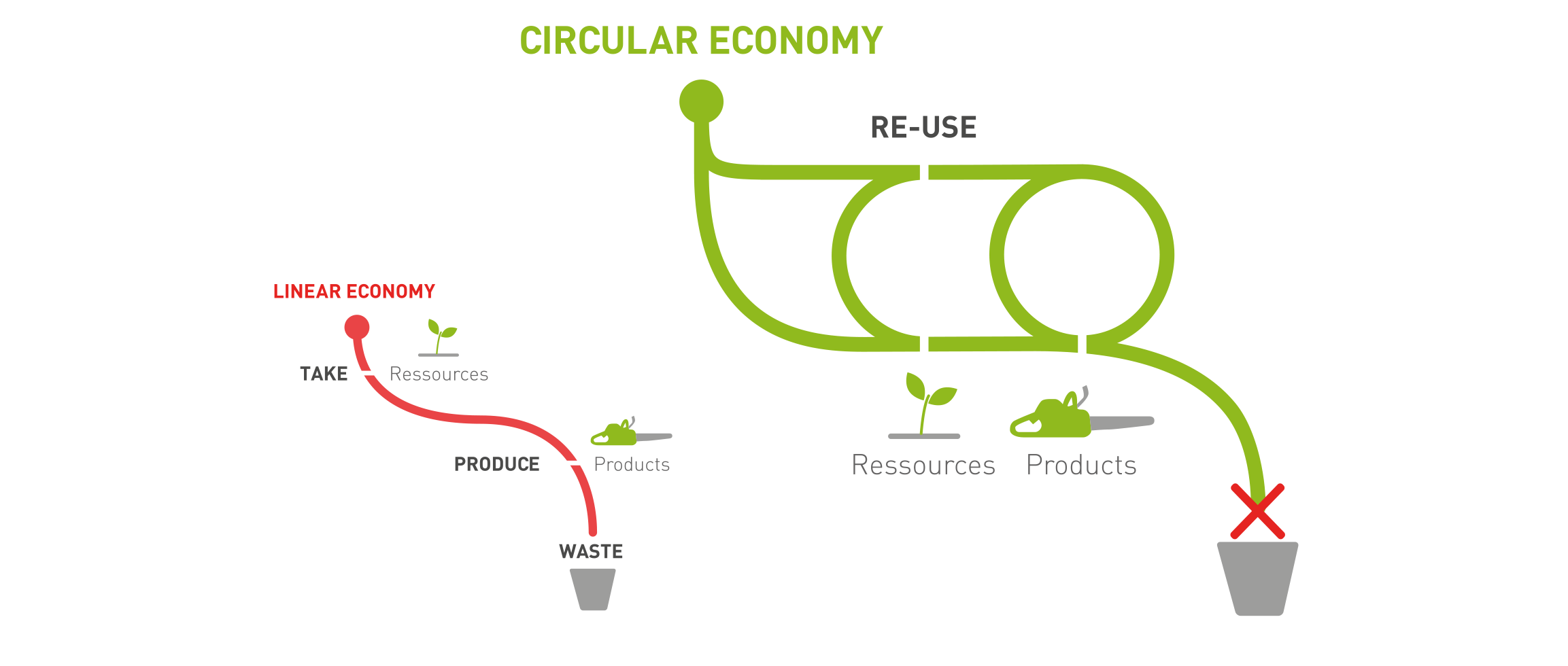

Sustainability is a widely used term and a generally desirable goal, but it can have different meanings and effects depending on the context and area of application. In terms of product development, sustainability means that products are designed, manufactured and used in such a way that they are economically, socially and ecologically compatible in the long term. BUSSE has drawn up criteria as guidelines for the development of high-quality and therefore durable products. Taking these aspects into account requires an interdisciplinary approach and the cooperation of all project participants.

Our range of services

- Bionics & lightweight construction

- Sustainable material concepts

- Implementation in development

- Further training & consulting

What makes a product sustainable?

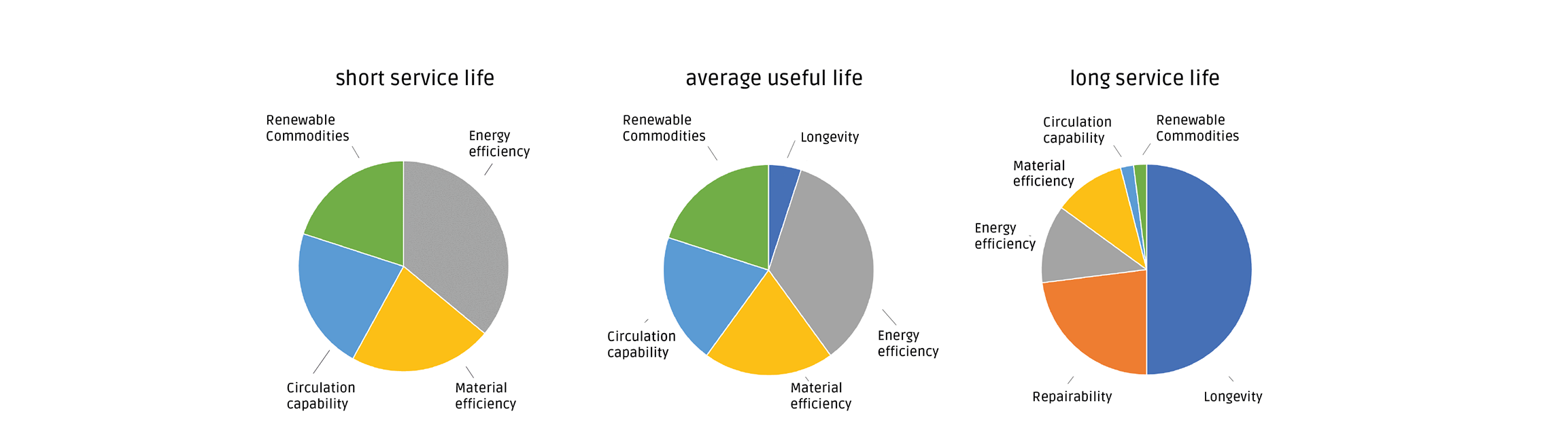

The following seven factors influence the sustainability of a product:

Longevity, reparability, material efficiency, energy efficiency, low problematic substances, renewable raw materials and recyclability. The weighting of these factors varies greatly depending on the intended use and lifespan of a product: for example, the use of renewable raw materials and recyclability is much more important for pure packaging than for a product with a long lifespan, where robustness and quality (and therefore even the use of additional, technically high-quality material) ensure that it lasts a long time.

Which factors are important and when?

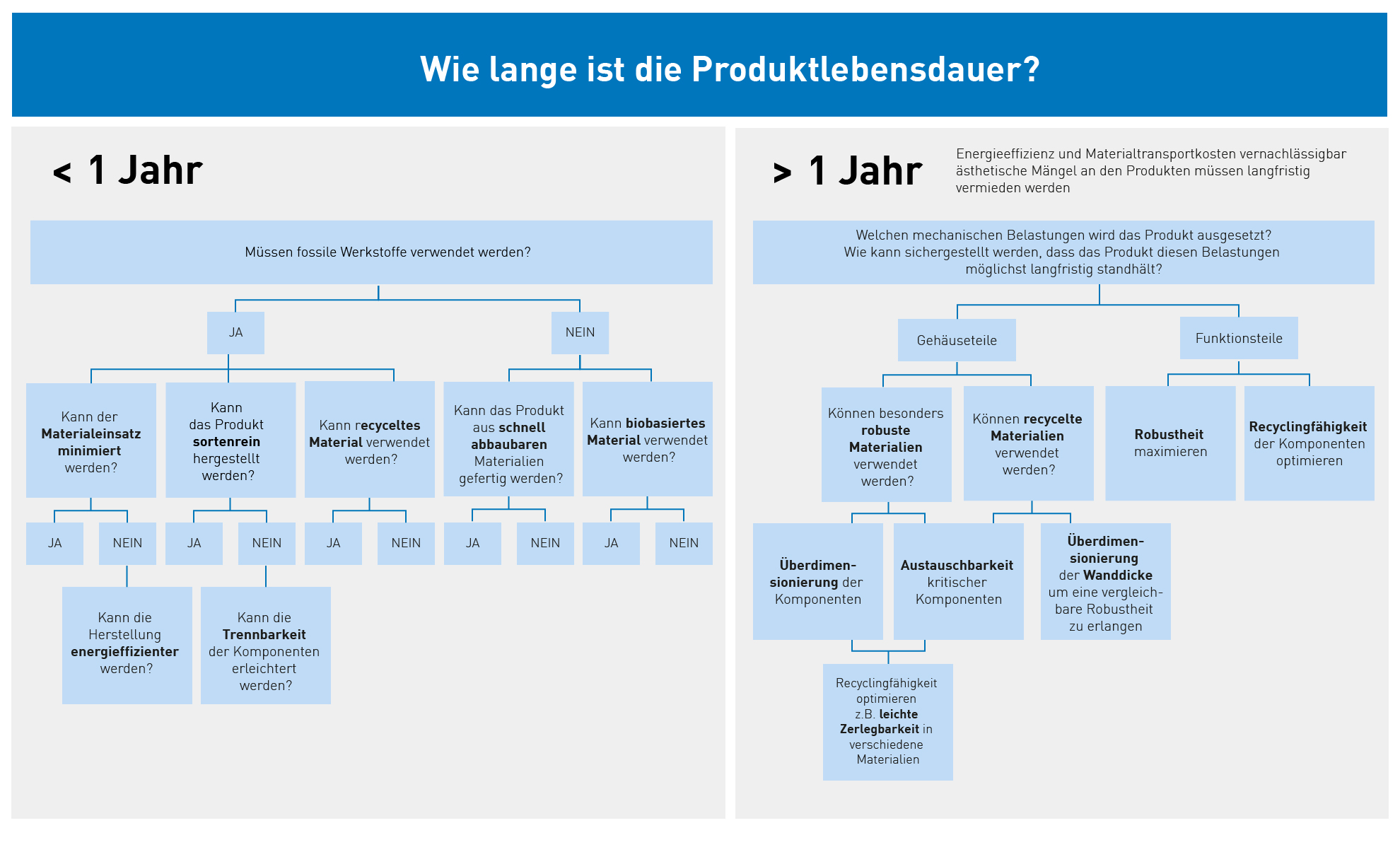

Most of the factors that influence the sustainability of a product are defined at the start of product development. One very important indicator is the product's useful life. We have created a small diagram to illustrate this.

The following questions should therefore be answered at certain points in the product development process:

Materials & Energy Requirements

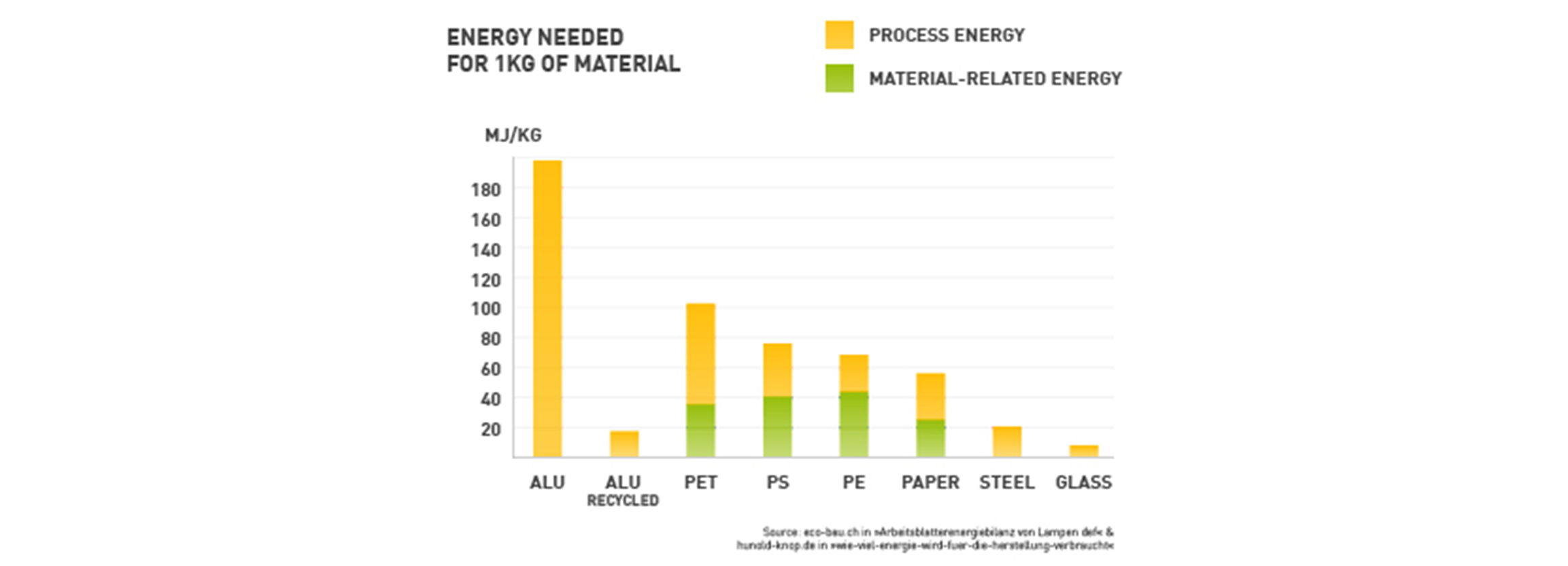

When selecting the material used, it is also important for us to consider the total energy requirement during production, processing and recycling. The transportation of the material to the actual production site of the product and the product to the end customer also generates a large proportion of the CO2 footprint.

Aluminum, for example, consumes an enormous amount of energy during initial production, but can be easily recycled. Recycled aluminum therefore consumes only a tenth of the energy required. A closed material cycle is very important here.

Steel and glass can be produced with little energy and are very easy to recycle with little loss of quality. Only the comparatively low density is an advantage of plastics. The term "material-related energy requirement" refers to the crude oil required as the starting point for plastic or the pulp for paper.

Plastics & recycling

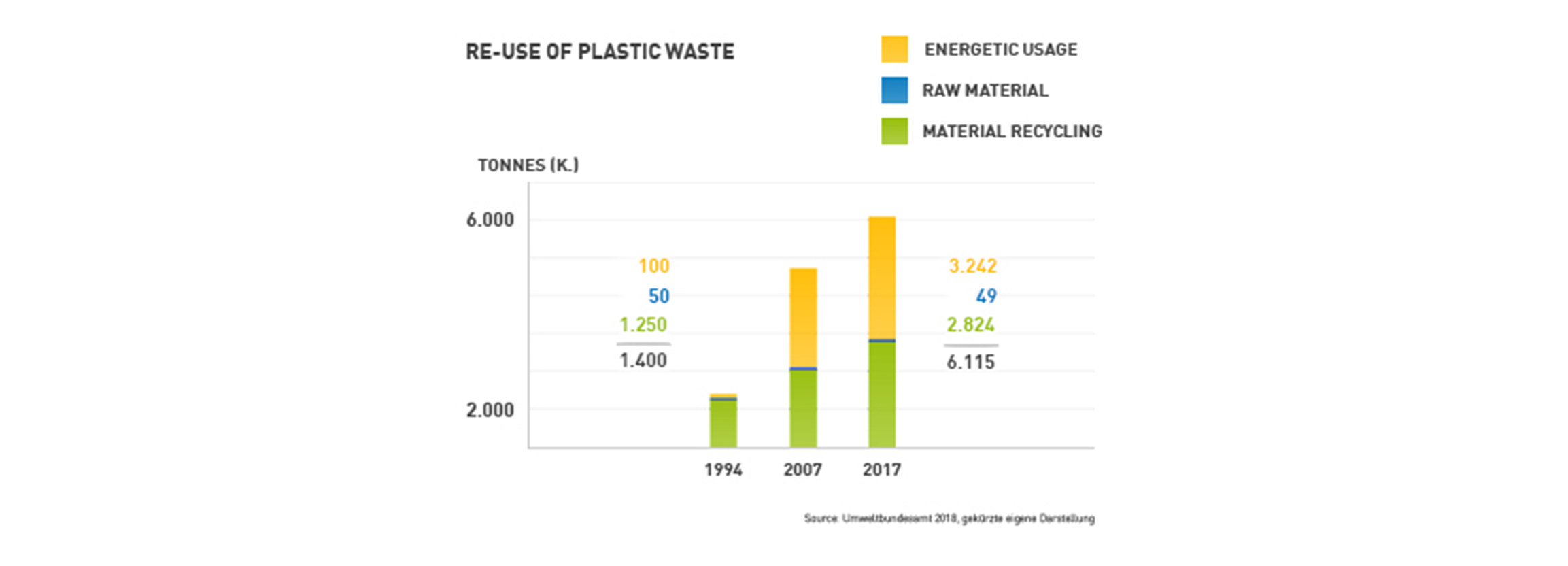

- The trend towards plastic recycling is fundamentally there, whereby the proportion used purely for energy has risen very sharply from 1994 to the present day.

has risen sharply. In our view, material recycling makes much more sense. - 1. in terms of materials: Collecting, shredding and re-injecting pure grades or adding them to a new product as recyclate.

- 2. raw material: mixed plastic is "oiled" using high heat and processed into high-quality new material.

As the process costs a lot of energy, this type of recycling is consistently low. - 3. energetic: The very high calorific value of the plastic is used in energy-intensive processes. Instead of fresh crude oil or hard coal, mixed plastic waste fuels the blast furnace. However, the sometimes highly toxic dust is problematic and has to be filtered out and disposed of.

Use of so-called sustainable materials

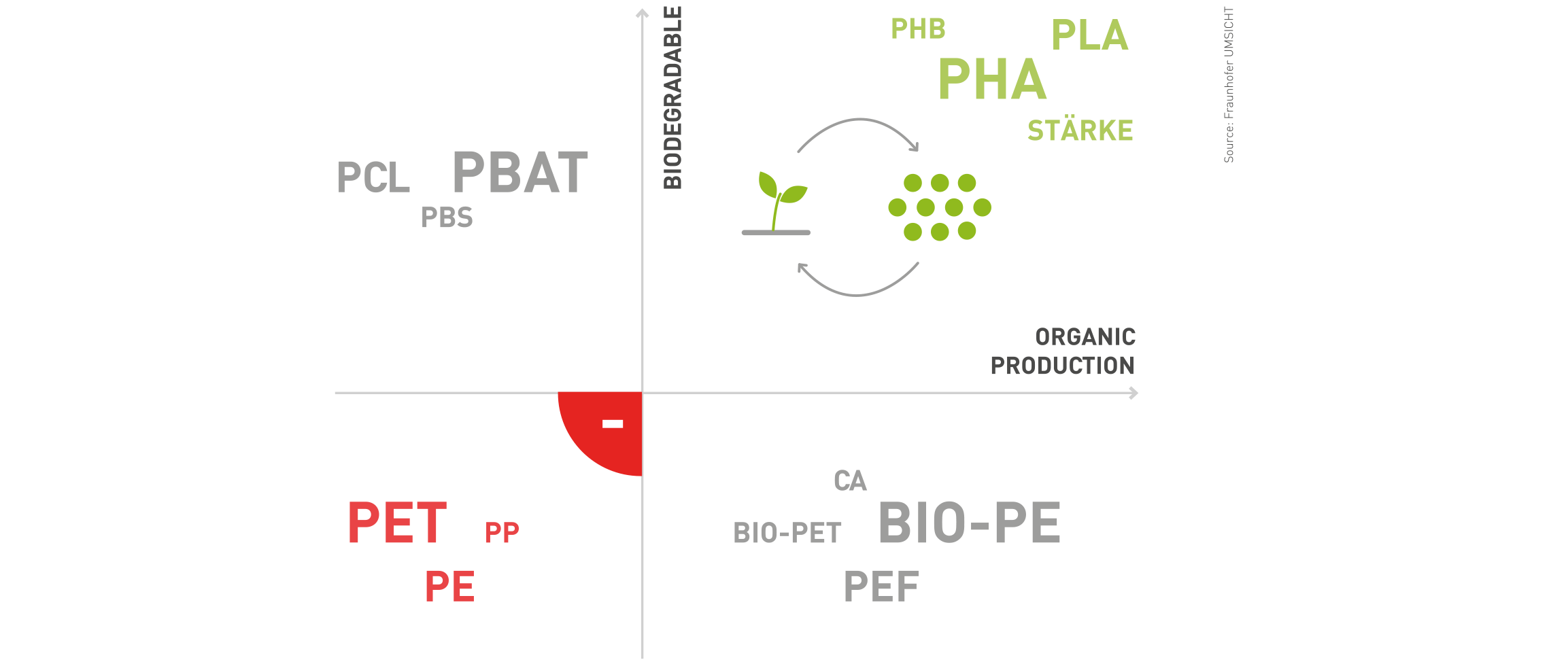

In general, almost any product can be made from recycled materials, but this must be known at the start of product development and the consequences must be considered. It is also important to be aware that simply replacing a plastic with a bio-based material does not necessarily make a product more sustainable.

In addition to conserving resources in their own production, such substitute materials unfortunately also have one or two limitations for the article itself:

- fluctuating moduli of elasticity and strengths that are significantly lower than those of conventional materials

- this leads to greater wall thicknesses and higher material usage to ensure the technical functions and geometries

- the material availability of the selected material must be taken into account

- the recyclability of the recycled materials, e.g. through the addition of natural fibers, is not yet guaranteed in most cases

- color variations and visual defects, which may lead to the product being thrown away earlier, even though it still fulfills its function perfectly!

Conclusion

Sustainability in product development is not only an ethical obligation, but can also bring economic benefits, as environmentally friendly and sustainable products are often better positioned on the market and customer demand increases. However, this requires a holistic way of thinking and the consideration of ecological, social and economic factors in order to develop the specific product in its application and usage context in a truly sustainable and successful way.

There is no standard solution for this issue: as explained above, it may well be more sustainable to specifically use high-quality, classic plastics in order to develop a product with a particularly long service life and robustness and thus be significantly more sustainable over its entire service life than if two products with renewable raw materials had to be produced, used and recycled for this period.

As product development experts with a keen eye for sustainability, we will be happy to support you with your next sustainable product development.

Just get in touch with us!